-

Syed Rashid Ahmed ButtShaanxi Chengda Industrial Furnace Co., Ltd. menyelesaikan pengoperasian tungku busur listrik, para pekerja dengan hati-hati bekerja sama dengan insinyur Chengda untuk belajar dan mengoperasikan peralatan,menunjukkan persahabatan yang mendalam dan kerja sama yang sangat baik antara rakyat China dan Pakistan.

Syed Rashid Ahmed ButtShaanxi Chengda Industrial Furnace Co., Ltd. menyelesaikan pengoperasian tungku busur listrik, para pekerja dengan hati-hati bekerja sama dengan insinyur Chengda untuk belajar dan mengoperasikan peralatan,menunjukkan persahabatan yang mendalam dan kerja sama yang sangat baik antara rakyat China dan Pakistan. -

AboubacarSetelah lebih dari 1 bulan produksi intensif dan debugging,2 set peralatan ruang pendinginan gas buang pertukaran panas telah berhasil dioperasikan ~ Semua personel yang terlibat dalam proyek telah bekerja keras~

AboubacarSetelah lebih dari 1 bulan produksi intensif dan debugging,2 set peralatan ruang pendinginan gas buang pertukaran panas telah berhasil dioperasikan ~ Semua personel yang terlibat dalam proyek telah bekerja keras~ -

Ji-hwanSelamat hangat Shaanxi Chengda Industrial Furnace Manufacturing Company di Korea Selatan,Penginstalan peralatan tungku peleburan logam mulia di North Chungcheong County dan pembuatan yang cermat dan komisi yang ketat, menantikan masa depan di lebih banyak bidang untuk mencapai kerjasama saling menguntungkan!

Ji-hwanSelamat hangat Shaanxi Chengda Industrial Furnace Manufacturing Company di Korea Selatan,Penginstalan peralatan tungku peleburan logam mulia di North Chungcheong County dan pembuatan yang cermat dan komisi yang ketat, menantikan masa depan di lebih banyak bidang untuk mencapai kerjasama saling menguntungkan!

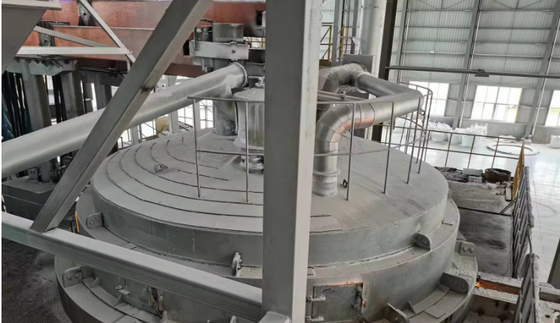

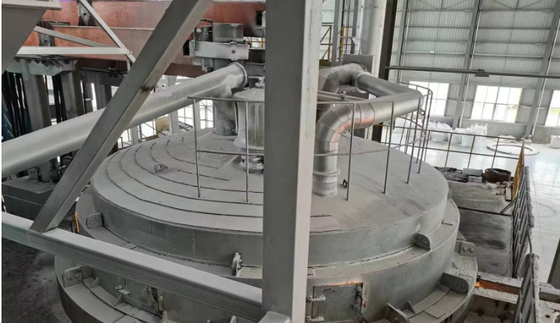

Tanur Korundum untuk Peleburan White Fused Alumina, Brown Fused Alumina, Dense Alumina & Zirconia Alumina

| Tempat asal | CINA |

|---|---|

| Nama merek | Shaanxi Chengda |

| Sertifikasi | ISO 9001 |

| Nomor model | Bernegosiasi berdasarkan kapasitas pemrosesan peralatan |

| Kuantitas min Order | 1 unit |

| Harga | The price will be negotiated based on the technical requirements and supply scope of Party A |

| Kemasan rincian | Diskusikan sesuai dengan persyaratan spesifik Pihak a |

| Waktu pengiriman | 2 ~ 3 bulan |

| Syarat-syarat pembayaran | L/C, T/T, Western Union |

| Menyediakan kemampuan | Rantai pasokan produksi lengkap, pasokan tepat waktu, dan memenuhi standar kualitas |

Hubungi saya untuk sampel gratis dan kupon.

ApaAPP:0086 18588475571

Wechat wechat: 0086 18588475571

Skype: sales10@aixton.com

Jika Anda memiliki masalah, kami menyediakan 24 jam bantuan online.

x| Menyoroti | tanur korundum untuk peleburan alumina,tanur peleburan alumina leburan,tungku pengolahan limbah berbahaya |

||

|---|---|---|---|

-

Kapasitas Suhu Tinggi

-

Beroperasi di2000°C+untuk melelehkan abrasif dan bahan tahan api yang sangat keras.

-

Ideal untuk memproduksiWhite Fused Alumina (WFA), Brown Fused Alumina (BFA), Dense Fused Alumina (DFA), dan Zirconia Corundum (AZS).

-

-

Aplikasi Lanjutan

-

Bahan abrasif: Membuat roda penggiling, kertas pasir, dan senyawa polishing presisi.

-

Perlengkapan api: Membuat lapisan murni untuk tungku, tungku, dan sendok.

-

Keramik khusus: Sintesis zirconia-hardened alumina (ZTA) untuk lingkungan yang ekstrim.

-

-

Teknologi Tungku

-

Desain Arc/Submerged Arc: Memastikan peleburan hemat energi dengan kontrol suhu yang tepat.

-

Sistem pendingin: Mencegah tekanan termal dalam crucibles/lining untuk memperpanjang umur.

-

-

Sifat-sifat Materiil yang Tercapai

-

Alumina Putih Yang Dipecat: ≥99% Al2O3, kekerasan tinggi (Mohs 9).

-

Zirconia Corundum (AZS): 10-40% ZrO2, ketahanan korosi / kejut termal yang superior.

-

-

Spesifikasi

1. Diameter dalam selubung tungku: Φ 2500mm;

2. kedalaman cangkang tungku: 2000mm;

3. Ketinggian tabung lurus: 1250 mm

4. Tinggi kerucut:750 mm

5Diameter elektrode:Φ 200mm;

6Diameter lingkaran distribusi elektroda: Φ 650mm;

7. Stroke elektrode: 1700 mm;

8. Kecepatan mengangkat elektroda:2-2.5m/menit;

9. Kapasitas nominal transformer: 1000KVA; ((Lang jangka kelebihan 20%, jangka pendek kelebihan 30%)

10. Tegangan utama trafo: 22KV;

Tegangan sekunder: 90 ~ 150V (tujuh tingkat) pengaturan tegangan listrik tanpa beban;

90 ~ 130 arus konstan; 130 ~ 150V daya konstan

arus utama: 26.275A;

Arus sekunder: 4446A(130V);

Metode pendinginan: OFWF (pendinginan air minyak yang kuat);

Atribut utama

Kemasan dan pengiriman